- Business Fields

- DTDesigner

DTDesigner

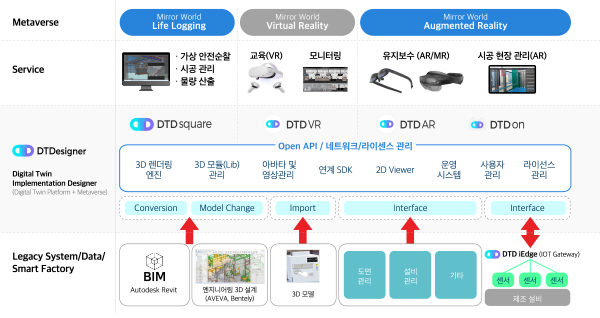

For the establishment of smart factories in high-tech industrial manufacturing facilities and processes, a platform for digital twins

-

-

"Building an Industrial Digital Twin allows seamless collaboration across departments. It enables

real-time conversion of design files and importing 3D models to create a virtual facility. This

opens up new avenues for efficient collaboration and optimization of production processes.

It serves as a perfect tool for innovation and collaboration in the high-tech industry. Easily convert design files, build a virtual facility with 3D models, simulate, and optimize. Don't miss the opportunity to advance collaboration across departments and enhance production process management.

Effortlessly import design files, implement them in 3D, and create a virtual facility with various departments. Optimize production processes through real-time data monitoring and simulation, predicting and addressing issues before they arise."

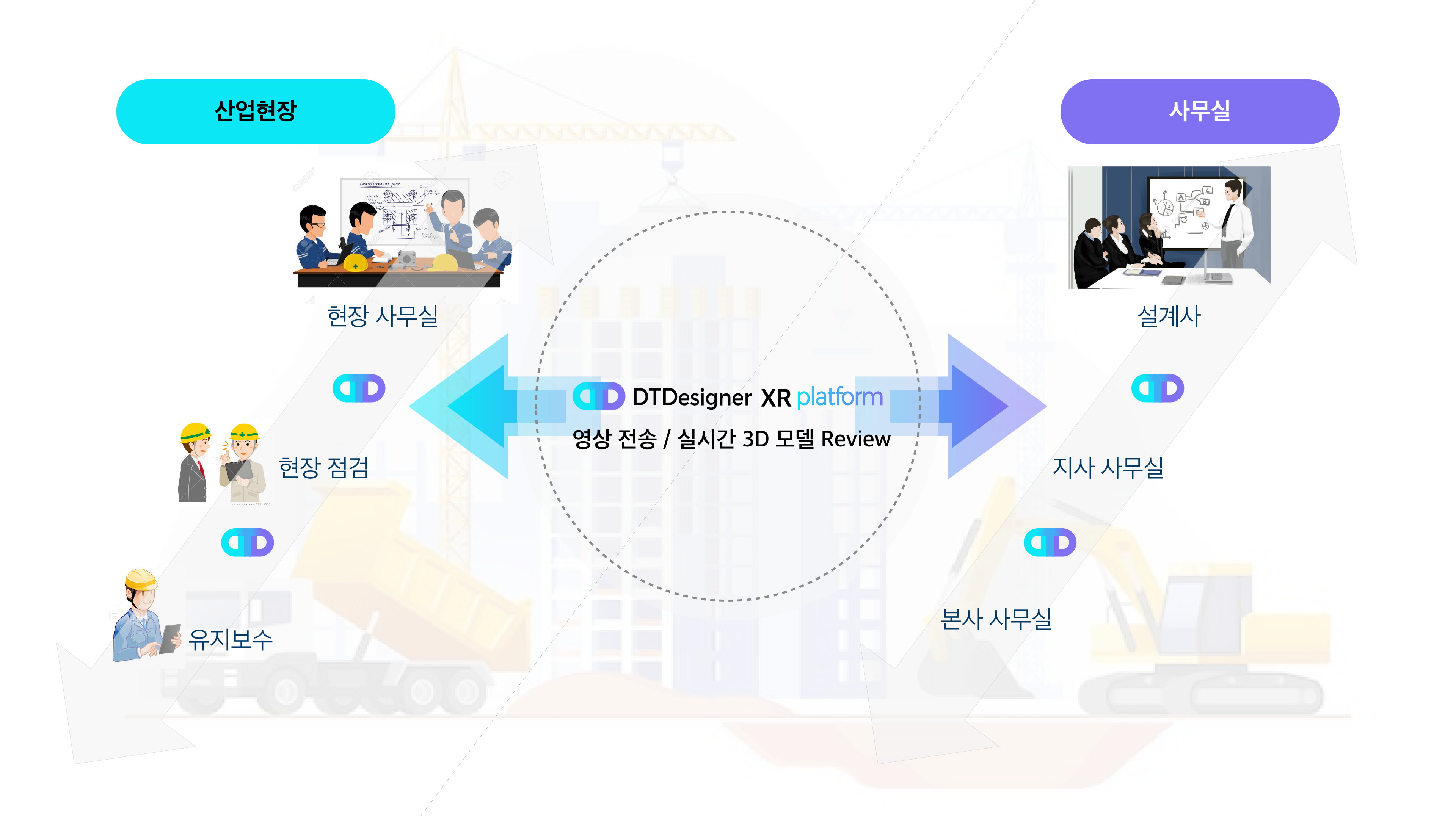

Real-time monitoring of all processes from design to construction

Real-time Collaboration

-

DTD square

A powerful tool to enhance real-time collaboration between the field and the office. It provides a virtual environment based on 3D design models, allowing visual confirmation of on-site conditions. This enables real-time awareness and quick response to issues or changes that occur in the field, fostering seamless communication between the office and the field. The virtual representation allows verification of equipment location, angles, sizes, and properties, ensuring alignment between design and actual on-site conditions.

The platform offers real-time monitoring of on-site operational situations by collecting sensor data and operational information, reflecting them in the virtual environment. This facilitates monitoring and optimization of production processes, enabling the detection of malfunctions or anomalies in advance for preventive measures. This contributes significantly to improving productivity and operational efficiency.

For real-time collaboration between the field and the office, the platform provides features that enable design and operations teams to work together in the virtual environment. They can collaboratively address issues and exchange information in real-time, enhancing communication and collaboration efficiency between the field and the office. Particularly, the ability to convey on-site issues through markup features and confirm them using 3D models facilitates more effective problem-solving. It serves as an efficient tool for sharing real-time 3D design models and operational situations between the field and the office, allowing for proactive response to changes and efficient collaboration to address issues and optimize production processes.-

Review

-

Monitoring

-

Providing interfaces for system integration.

-

-

DTD convert

The DTD converter transforms files into a format compatible with DTD (Document Type Definition), allowing functionalities like opening, editing, and saving in DTD Square, DTD On, DTD Builder & DTD Guide, and DTD AR. Through DTD conversion, users can experience a more streamlined and rapid collaborative design process. -

DTD AR

AR technology allows real-time on-site verification of virtual facilities in the high-tech industry. Users can use AR features to place virtual facilities on-site and visually confirm them in the actual environment. This enables easy assessment of the alignment between the designed model and the on-site conditions, facilitating quick identification and resolution of issues.

The system provides a function to compare the real-time status of the construction site with design information. Through AR, users can combine on-site visuals with design information to verify the alignment of construction progress and design. This helps improve construction efficiency and allows for swift responses in case of issues.

The platform offers a feature to check the alignment between design and construction using Building Information Modeling (BIM) models. BIM models can be edited and transformed for visualization in the AR environment, enabling users to visually confirm the alignment of design and construction. This ensures accurate construction results and minimizes problems during the construction process. By leveraging AR capabilities, users can experience virtual spaces on-site, facilitating the verification of design and construction alignment. It contributes to efficient on-site management and quick issue resolution.-

AR technology enables the verification of virtual facilities, allowing for quick confirmation of alignment with the design and swift responses.

-

Real-time comparison of construction progress and design information enhances construction efficiency and enables rapid responses.

-

Using BIM models

for verifying alignment between

design and construction ensures accurate

construction results.

-

-

DTD on

It enables real-time communication and information exchange between the field and the office. Issues or changes occurring in the field are immediately communicated to the office, allowing for swift responses. Similarly, opinions or instructions from the office regarding issues can be conveyed in real-time to the field. This establishes seamless communication between the field and the office, facilitating quick problem resolution.

The provided 3D model allows visual confirmation of on-site issues and modifications. Problems or modifications from the field can be marked up on the model, providing an easy way for the office to understand the details. Additionally, the 3D model visualizes the overall status of the facility, aiding collaboration and decision-making for both the field and the office.

The platform offers various content insertion and storage capabilities, efficiently managing materials such as videos, drawings, and documents. Users can easily insert and store videos, photos taken on-site, design drawings, and relevant documents. The system enables quick searches and utilization of necessary information at any time, enhancing the efficiency of data management and providing accurate information required for project progression.-

It enables real-time communication of on-site changes and allows confirmation through a 3D model.

-

The markup feature facilitates effective communication and resolution of on-site issues, while the capability to insert and store various contents supports efficient data management and collaboration.

-

-

DTD builder

& DTD guideThe 3D model allows the application of various effects, making the manual more vivid. It enables visual demonstration of product operation methods or detailed explanations of the product's structure and operation. The animation feature is utilized to clearly convey the operational principles and procedures of the product, providing users with a sense of manipulating the product as if in real life.

The manual easily incorporates videos, drawings, and documents, allowing for the provision of more information. It can display the product's composition or assembly sequence through drawings and provide detailed explanations of the product's features or usage methods through documents. Additionally, it offers a function to reference internet sites, making it easy for users to obtain additional necessary information.

It enhances manual creation more effectively. With an intuitive interface and various functions, users can easily write and edit manuals. Augmented reality technology is employed to enable users to virtually experience the actual product. This allows users to gain a clearer understanding of the product and efficiently perform tasks according to the guidance. Combining innovative technology and creative features, it introduces a new paradigm for manual creation. Start your experience of creating new manuals with us.-

Providing vivid visual explanations and various content, it clearly communicates the operation of the product through 3D models and animations. It offers more information through videos and documents.

With intuitive editing features for user convenience and augmented reality technology, it enables more effective manual creation.

-